Green Hydrogen Manufacturing Plant Project Report 2024: Required Materials and Setup

A Green Hydrogen Manufacturing Plant in 2024 requires purified water, renewable energy (solar, wind, or hydro), and electrolyzers (alkaline or PEM) for electrolysis. Key infrastructure includes hydrogen compressors, storage tanks, safety systems, and power management. Investment covers land, renewable energy setup, and equipment. Government incentives and environmental compliance are critical, with a focus on reducing carbon emissions.

As the world increasingly turns its focus to sustainable energy solutions, green hydrogen has emerged as a promising alternative to fossil fuels. Derived from renewable energy sources, green hydrogen is produced through the electrolysis of water, where electricity from sources like solar or wind is used to split water molecules into hydrogen and oxygen. This clean energy carrier offers numerous applications across various sectors, including transportation, industry, and energy storage, making it a pivotal player in the transition toward a sustainable energy future. This comprehensive project report explores the market potential, manufacturing processes, equipment requirements, financial considerations, and regulatory landscape involved in establishing a Green Hydrogen Manufacturing Plant.

Market Potential for Green Hydrogen

The market for green hydrogen is witnessing rapid growth, driven by several key factors:

Global Decarbonization Goals: With countries worldwide committing to reducing carbon emissions, green hydrogen provides a viable path to achieving these targets, particularly in hard-to-abate sectors like steel and cement.

Government Support: Many governments are implementing policies and subsidies to promote the development of hydrogen infrastructure, which will significantly boost demand for green hydrogen.

Investment in Renewable Energy: As the cost of renewable energy sources continues to decline, green hydrogen production becomes increasingly economically viable, encouraging investment from both public and private sectors.

Diverse Applications: Green hydrogen can be utilized in various sectors, including transportation (fuel cells for vehicles), industrial processes (as a feedstock), and as a means of energy storage, enhancing its market potential.

Technological Advancements: Ongoing research and innovation in electrolyzer technology and hydrogen storage solutions are expected to improve the efficiency and reduce the costs of green hydrogen production.

Get a Free Sample Report with Table of Contents @ https://bityl.co/RxLQ

Manufacturing Process of Green Hydrogen

The production of green hydrogen primarily involves the process of electrolysis, where electricity is used to split water into hydrogen and oxygen. Here’s a detailed overview of the manufacturing process:

1. Electrolysis of Water

Electrolysis is the core process in green hydrogen production. It can be broken down into the following steps:

Electrolyzer Setup: The electrolyzer is the heart of the process, consisting of an anode and a cathode separated by an electrolyte membrane. When a direct current is applied, water molecules are split into hydrogen ions and oxygen.

Collection of Hydrogen and Oxygen: The hydrogen gas is collected at the cathode while oxygen is released at the anode. The produced hydrogen can then be stored or utilized immediately.

2. Power Supply

A reliable power supply is crucial for electrolysis. Renewable energy sources, such as solar panels or wind turbines, are typically used to provide the electricity needed for the process. The integration of renewable energy ensures that the hydrogen produced is indeed “green” and free from carbon emissions.

3. Storage and Compression

Once produced, hydrogen must be stored for later use. Various methods of storage can be employed:

Compressed Gas Storage: Hydrogen can be compressed and stored in high-pressure tanks. This method is commonly used due to its simplicity and effectiveness.

Liquid Hydrogen Storage: For large-scale applications, hydrogen can be cooled to very low temperatures to convert it into a liquid state, allowing for higher energy density and storage capacity.

Metal Hydrides: Hydrogen can also be stored in solid form using metal hydrides, which can absorb and release hydrogen gas when heated.

4. Distribution

After production and storage, hydrogen needs to be distributed for use. This can involve:

Pipeline Transport: For large-scale hydrogen delivery, dedicated pipelines can transport hydrogen from production facilities to end-users.

Tankers and Trucks: For smaller quantities or in areas lacking pipeline infrastructure, hydrogen can be transported using specialized tankers.

Equipment and Machinery Required

To establish a Green Hydrogen Manufacturing Plant, several types of machinery and equipment are essential for efficient production. Some of the key equipment includes:

Electrolyzers: The main equipment for producing hydrogen through electrolysis. Various types, including alkaline, proton exchange membrane (PEM), and solid oxide electrolyzers, can be utilized depending on specific project requirements.

Renewable Energy Sources: Solar panels, wind turbines, or any other renewable energy systems to provide the necessary electricity for electrolysis.

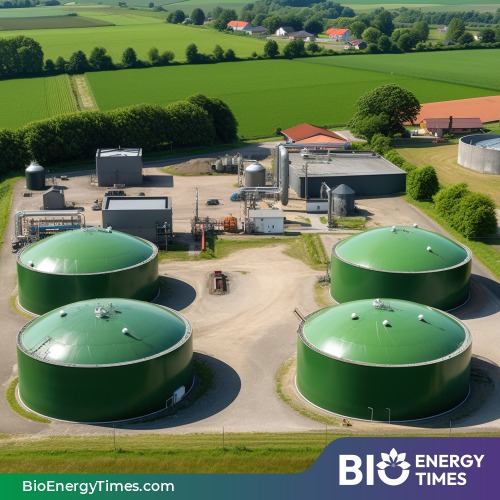

Storage Tanks: High-pressure tanks or cryogenic storage systems for storing hydrogen gas or liquid hydrogen.

Compression Units: Equipment for compressing hydrogen gas to the required pressure for storage and transportation.

Safety Equipment: Given the flammability of hydrogen, safety systems, including gas detectors and ventilation systems, are crucial to ensuring safe operations.

Financial Considerations and Investment

Setting up a Green Hydrogen Manufacturing Plant involves significant investment, but the potential returns can be substantial given the growing demand for green energy solutions. Key financial considerations include:

Initial Capital Investment: The investment required can range from $1 million for small-scale operations to over $100 million for larger facilities, depending on the capacity and technology used.

Operating Costs: Operating expenses include raw materials (water and electricity), labor, maintenance, and insurance.

Return on Investment (ROI): Depending on the market conditions, operational efficiency, and the technology used, investors can expect a positive ROI within 5 to 10 years.

Regulatory Considerations

Establishing a green hydrogen manufacturing facility is subject to various regulatory requirements, primarily focused on environmental sustainability, safety, and product standards.

Environmental Regulations: Compliance with local, national, and international environmental regulations is crucial. This includes minimizing emissions, waste management, and adherence to sustainable practices.

Safety Standards: Given the risks associated with hydrogen production and storage, compliance with safety standards is essential to ensure worker safety and prevent accidents.

Permitting: Obtaining the necessary permits and licenses from regulatory authorities is a key step in the project development process. This may include environmental impact assessments and safety inspections.

Environmental Impact and Sustainability

Green hydrogen production offers numerous environmental benefits, including:

Reduction in Carbon Emissions: By utilizing renewable energy sources for production, green hydrogen significantly reduces greenhouse gas emissions compared to fossil fuel-derived hydrogen.

Energy Storage Solution: Green hydrogen can serve as an energy storage medium, helping to balance supply and demand in renewable energy systems, particularly in regions with high variability in energy generation.

Minimal Water Usage: While water is a key raw material in hydrogen production, advanced technologies and practices can minimize water consumption and ensure efficient use.

FAQs

1. What is green hydrogen?

Green hydrogen is hydrogen produced through the electrolysis of water using renewable energy sources, resulting in no carbon emissions.

2. How is green hydrogen different from traditional hydrogen?

Traditional hydrogen is often produced from natural gas through processes like steam methane reforming, which emits carbon. Green hydrogen is produced sustainably, making it a cleaner alternative.

3. What are the main applications of green hydrogen?

Green hydrogen is used in fuel cells for vehicles, as a feedstock in industrial processes, and for energy storage.

4. How is green hydrogen stored?

Green hydrogen can be stored as compressed gas, in liquid form, or as metal hydrides, depending on the application and required storage capacity.

5. What is the investment required to set up a green hydrogen plant?

The initial capital investment can range from $1 million for small-scale operations to over $100 million for larger facilities, depending on various factors.

6. Is green hydrogen safe?

While hydrogen is flammable, with proper safety measures, control systems, and regulations, green hydrogen can be produced and stored safely.

Acquire unparalleled access to critical industry insights with our comprehensive market research reports, meticulously prepared by a team of seasoned experts. These reports are designed to equip decision-makers with an in-depth understanding of prevailing market trends, competitive landscapes, and growth opportunities.

Our high-quality, data-driven analysis provides the essential framework for organisations seeking to make informed and strategic decisions in an increasingly complex and rapidly evolving business environment. By investing in our market research reports, you can ensure your organisation remains agile, proactive, and poised for success in today’s competitive market.

Don’t miss the opportunity to elevate your business intelligence and strengthen your strategic planning. Secure your organisation’s future success by acquiring one of our Expert Market Research reports today.

Source Link : https://www.openpr.com/news/3680400/green-hydrogen-manufacturing-plant-project-report-2024